By Catherine Drake, Invertebrate Zoology Lab

A lot of people make bucket lists, such as the "before I turn 30" list or the classic "before I kick the bucket" list. My personal bucket list, what I call the "self-sufficiency" list, comprises of learning various essential skills in order to be more reliant on myself in everyday life. Last semester, those of us taking MS 202 Marine Instrumentation (deemed the "Fab Four" because there are four of us taking the class) with Dr. Kenneth Coale learned such essential skills for our futures in marine science that will allow us to think critically if we need to construct something or if faced with a mechanical problem.

Kenneth's classic Coale-ism, "if it's worth doing, it's worth overdoing," is the theme of this class. That means the Fab Four do a lot of planning, trying out the product, and making small tweaks for the best outcome possible, which teaches us to think critically about our designs.

Our latest fabrication project comes from Dr. Ivano Aiello and the Geological Oceanography lab.

The problem: Ivano and his team need a contraption that will allow them to core up to 15 feet deep into sediment. They would like to better understand sedimentation that has occurred over time in locations such as Elkhorn Slough and Pescadero Point.

The solution: a Vibracore. This machine will create vibrations to decrease friction between sediments and the core and will force the core into the ground. It is designed for the purpose of obtaining deep cores, so it is a perfect tool for Ivano's current project.

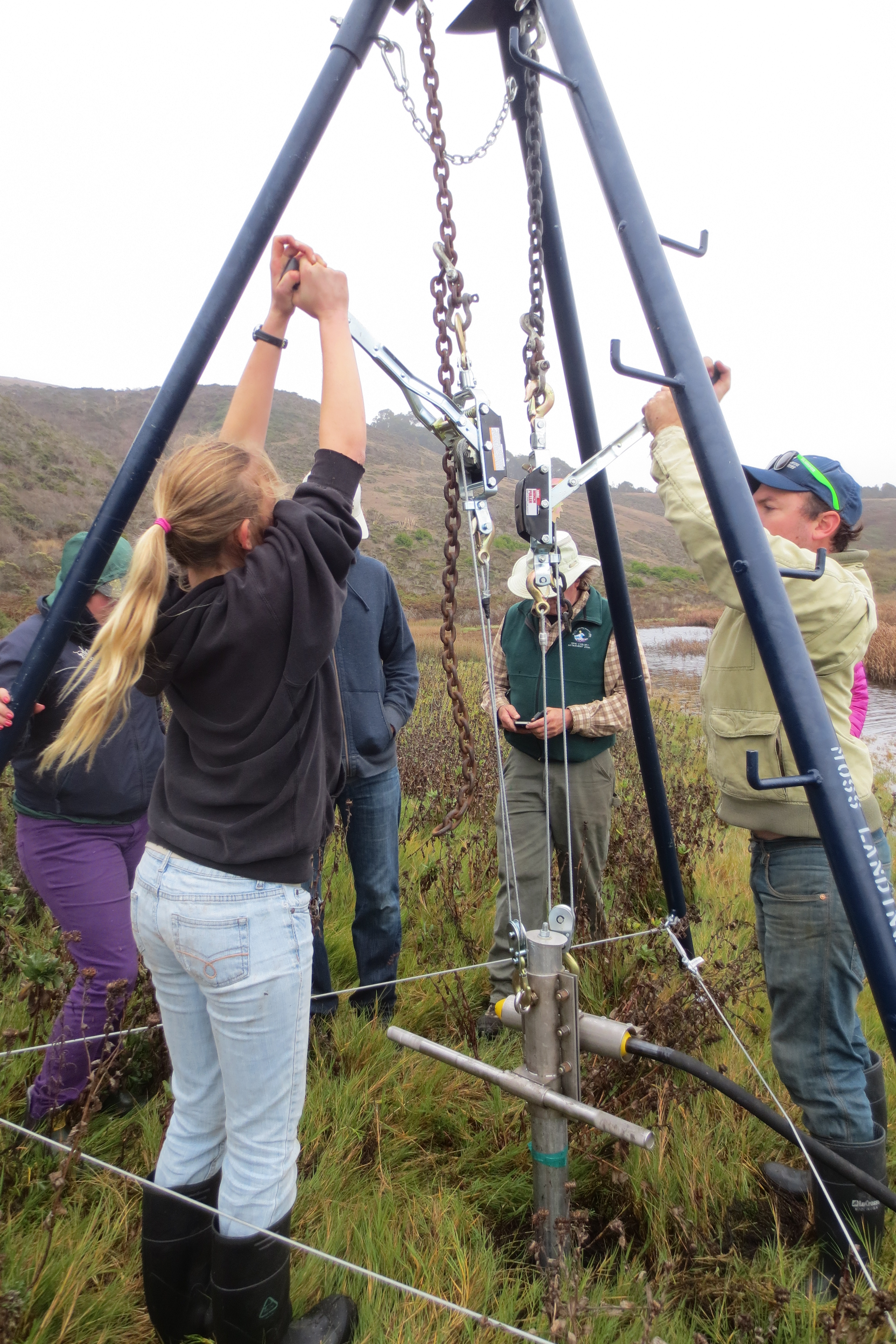

The parts: 1) a Vibracore head with a modification to attach to the core, and 2) a tripod to hold the core in place as coring occurs and to remove the core once coring ceases.

Our major contribution to the project was the 3 meter tall tripod using scraps from previous projects and local scrap yards. The tripod consisted of three 2-inch pipe legs, one of which had spokes welded onto it for climbing, and a top plate that would hold come-alongs to retrieve the core from the ground.

Once the parts were completed, we took to the field for a trial!

We trekked out to Psecadero Point to obtain two cores for Christina Volpi, a graduate student in the Physical Oceanography lab, who needed to collect samples for her thesis work. As the Vibracore head hummed, the core was shot into the ground and the sediment was contained.

The cores were retrieved and were taken back to the lab for sectioning. Soon, they will be analyzed and the data will be incorporated into Christina's Volpi's thesis.

With the opportunity to take MS 202 Marine Instrumentation, combined with the ingenuity of Dr. Kenneth Coale, the Fab Four obtained skills necessary for being self sufficient in a marine setting (not to mention a resounding checkmark for my bucket list). We sharpened knives, ground rust off of tools, assembled microspears, used both a lathe and a mill, welded metal objects together, and built a Vibracore for extreme coring capabilities. It was a productive semester, and there was certainly a rewarding feeling in getting to watch the fruits of our labor work successfully when in the field.