What is a bioreactor?

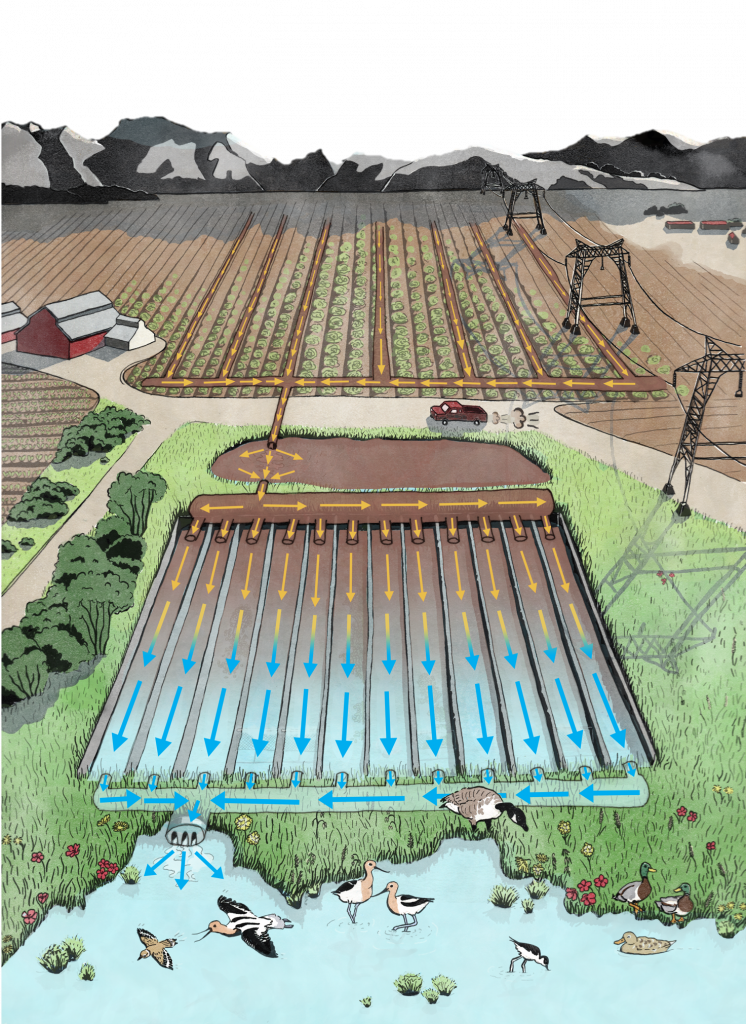

Bioreactors are used to reduce water pollution. In areas with significant agricultural land use, pollutants found in fertilizers and pesticides can runoff into local creeks and sloughs and contaminate the water. Bioreactors encourage the growth of helpful bacteria that remove nitrogenous pollutants from the water runoff as it flows through the bioreactor. These bacteria thrive in wood chips, native wetland plants, and other substrates used in bioreactors.

Filtering agricultural water runoff using bioreactors can help to reduce harmful algal blooms in downstream creeks, estuaries, and even in the Monterey Bay. Without treatment, these algal blooms can be toxic to both humans and animals.

Bioreactors are often paired with treatment wetlands to further enhance water quality downstream. In addition to improving water quality, treatment wetlands help provide wildlife habitat and flood control. A paired bioreactor and treatment wetland system is a cost-effective method for mitigating the environmental impacts of agriculture and improving water quality in farming communities.

Animation by Mona Luo

Types of Bioreactors

Experimental Multi-chamber Bioreactor

CCWG's Castroville Slough Bioreactor is an experimental, 12-channel bioreactor. Each channel is 80 feet long, 5 feet wide, and 2 feet deep. The 12 channels each have one of three treatments: wood chips, wetland vegetation, or control (no treatment). This bioreactor system allows our field crew to collect data from each of the three channel types and determine which treatment best removes pollutants from agricultural water runoff. This data helps us determine how farmers can create the most effective bioreactor design based on their total land area and nitrogen input (excess nutrients in fertilizers and pesticides).

Illustration by Alex Boersma

Woodchip Bioreactor

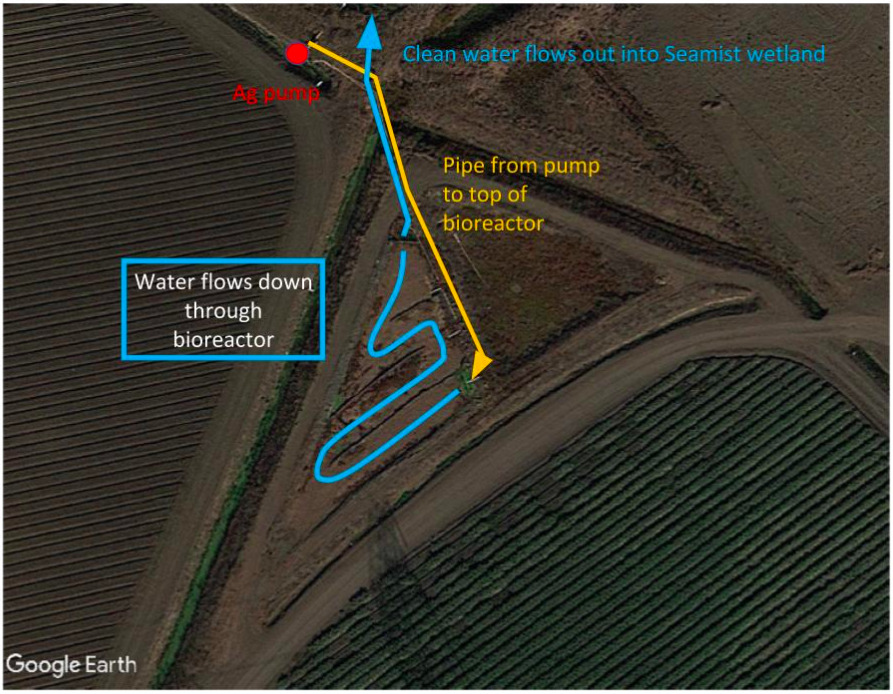

In 2006, CCWG built a treatment wetland at Sea Mist Farms to help clean the agricultural water runoff from adjacent farms. Three ponds and connecting channels totaling more than 21 acres of shallow freshwater habitat were created on the Sea Mist parcel, just downstream of the Union Pacific Railroad crossing.

In 2016, CCWG added a bioreactor to the water treatment system at Sea Mist Farms. This bioreactor (pictured below) is one-acre, triangular-shaped, and has a single sinuous channel filled with wood chips. Water runs off agricultural fields (predominantly growing artichokes and Brussel sprouts) and into a series of ditches before it is pumped into the bioreactor. The carbon-rich woodchips in the bioreactor promote the denitrification (removal of nitrogen) of water as it flows through the system. Different from the multi-chamber bioreactor, this bioreactor is very cost-effective and simple. Farmers can build woodchip bioreactors in smaller, unused portions of their land to clean the water in drainage ditches before it reenters the watershed.

How can I create my own bioreactor?

Are you a farmer interested in learning how you can design your own bioreactor treatment system? Go to the resources section at the bottom of the page and select the "Bioreactor Calculator" icon. There, you can input parameters that are specific to your farm to determine what bioreactor specifications will allow you to meet water quality standards and reduce environmental impact. The Bioreactor Calculator will help you calculate both Percent Reduction (how much nitrate the bioreactor will remove from the water being pumped through the system) and HRT or Hydraulic Residence/Retention Time (how long the water needs to stay in the bioreactor to remove the desired amount of nitrate).